John Petersen

Today we have a bit of a hodge-podge as I consider sticker shocks, delays and manufacturing capacity forecasts in the vehicle electrification and energy storage sector. Since the sticker shock and delay discussions involve recent news, I’ll touch on them first before getting into the fuzzier aspects of manufacturing capacity forecasts.

I’d like to begin with a note of thanks to one of my Seeking Alpha followers, MRTTF, for sending me links to both news stories. For readers who don’t delve into the comment streams, MRTTF is a PhD chemist who works in R&D for a leading domestic lithium-ion battery manufacturer. I truly appreciate his willingness to correct me when I make mistakes, provide technical detail that’s beyond my competence and remind overly optimistic readers “lithium-ion is best for applications where size and weight are of paramount importance and cost is no object.”

Sticker shock from Nissan

It will come as a shock to many EV evangelists who expected the Leaf from Nissan Motors (NSANY) to be a cheap plug-in vehicle, but an article in Wednesday’s Mainichi Daily News reported that Nissan has set the price for the Leaf at around 4 million yen, which works out to roughly $44,000 at current exchange rates. Given the earlier known price points of $40,000 for the GM Volt and $51,000 for the i-MiEV from Mitsubishi Motors (MMTOF.PK), I would have been surprised by a lower number. I may be wrong, but I just don’t see consumers lining up around the block.

Nissan will no doubt develop a slick promotional campaign to show how the total cost of owning and operating a Leaf will be comparable to the cost of a conventional vehicle after accounting for Federal tax credits, available state and/or local subsidies and the expected spread between gasoline and electricity prices. My sense is the explanation will not be eagerly embraced by budget conscious consumers who expect clear short-term savings instead of a potential long-term breakeven. I have no doubt that Nissan will sell modest Leaf fleets to governments, car rental companies, utilities and corporations that are so desperate to project a green image that they’ll buy a wasteful status symbol to do so. However once we get past a small and intensely vocal group of philosophically committed consumers, I think the Leaf will be little more than a curiosity item to lure shoppers into Nissan showrooms where they’ll end up buying sensibly priced fuel efficient vehicles without plugs.

Delays from BYD

A more ominous news item out of China that went largely unnoticed was BYD Company Ltd.’s (BYDDY.PK) decision to go back to the drawing board and delay the widely heralded commercial rollout of its Model E6 electric car. A Bloomberg article from Monday reported that after selling a total of forty-eight F3DM plug-in hybrids to government and corporate customers in 2009, BYD has given up on its ambitious plans to mass produce electric cars in China by the middle of this year. Instead, it will build a fleet of 100 taxis for its hometown of Shenzhen, China. Many will be gravely disappointed with the decision. I just think it makes good sense.

One of my longest standing objections to the plug-in vehicle mania has been an almost total absence of long-term testing by normal people in real world conditions. Automobiles are incredibly complex machines and humans are infinitely creative when it comes to finding (or is it creating?) problems that engineers can’t even imagine. Under those circumstances, I’ve always believed the first step had to be a small and closely monitored fleet that operates in a small area, performs a limited function and can be promptly repaired when the inevitable problems arise. Once the first phase testing is completed and the common problems are solved, the next logical step is a larger fleet of several thousand vehicles that will be placed in the hands of a wider variety of users, but still limited to a small area where they can be properly monitored and quickly repaired when new problems arise. Once the second phase testing is completed and the second level of problems are solved, the next logical step is an even larger and more widely dispersed fleet that will identify and solve additional problems, and hopefully result in a product that’s ready for commercial sale to customers who expect quality and reliability.

The best analog for the process outlined above is the testing and approval of new drugs, a time-honored process that every pharmaceutical in the world goes through before it can legally be sold to consumers. The process is cumbersome, time consuming and expensive, but even then it’s not perfect. Drugs are subjected to rigorous testing and monitoring because dangerous ones can be grave threats to health and safety. It strikes me as preposterous that automakers would expect, or for that matter even want, a free pass to sell potentially dangerous vehicles to customers (or is it lab rats?) without widespread and rigorous testing. I suspect that BYD will be the first of many automakers to delay their commercial rollout plans in favor of the prudent and comprehensive long-term testing that other industries conduct as a matter of course. The one thing I can pretty much guarantee is that trial lawyers everywhere will be lying wait for companies who don’t.

Capacity forecasts from Roland Berger Strategy Consultants

I’ve previously mentioned a recent Forbes article that raises the specter of a lithium-ion battery glut within a few years. I’ve also said that I don’t expect a glut for several reasons including faster than anticipated growth in the HEV market and rapid growth in the electric two-wheeled vehicle market. Other reasons for my confidence include 30 years of experience that new technologies invariably create new demands that were not foreseen by their developers, and the fact that plans are always subject to change, delay and cancellation.

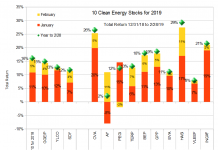

In a recent presentation titled “Powertrain 2020; Li-ion Batteries – The Next Bubble Ahead?” Roland Berger Strategy Consultants presented the following graphic analysis of announced capital spending plans for the 20 largest lithium-ion battery manufacturers in the world. It reflects both cumulative spending through 2015 and the estimated production capacity of the planned factories. For presentation purposes, an EV equivalent is defined as a 25 kWh battery pack.

At current exchange rates, €8.2 billion is roughly $11.2 billion for 2.6 million EV equivalents, or 65 million kWh. The three companies with the most ambitious spending plans are AESC, Nissan’s battery manufacturing joint venture, LG Chem, which will make battery cells for the GM Volt, and China’s BYD. Curi

ously, the company with the most modest plans is Panasonic EV Energy, a unit of Toyota Motors (TM), the inventor of HEV technology and the dominant manufacturer in that space. While I have to confess a morbid fascination with the idea that the company with the most vehicle electrification experience is the one with the most modest spending plans, I also suspect there may be a deeper message for the perceptive.

Given the level of disappointment I expect over the price of the Leaf, I wouldn’t be surprised to see AESC adjust its capital spending plans. The same goes for BYD, which won’t need to build battery plants if it isn’t going to be building electric vehicles to use the batteries. If other automakers follow BYD’s lead and decide to take a traditional and litigation resistant approach to product development and testing, other capital spending plans are likely to be pared, delayed, shelved or cancelled. In the final analysis, the only battery plants that seem certain to be built are the ones that will be financed by the $1.2 billion in ARRA battery manufacturing grants that President Obama announced last August.

I’m a dyed in the wool plug-in vehicle critic because my calculations prove that the concept is inherently wasteful. While the message is not always clear, I’m a big fan of lithium-ion batteries for applications where size and weight are mission critical constraints and cost is a secondary consideration. When I criticize A123 Systems (AONE) or Ener1 (HEV), my criticism is leveled at applications that I see as foolish waste of good and valuable products. I remain convinced that every company that builds a battery manufacturing plant and brings a good product to market will have all the business it can handle. However I’d feel much better if everybody stopped chasing unicorns, cost effective plug-in vehicles and other mythical beasts.

Disclosure: I have no ownership or other interests in any of the companies mentioned.

thank you for a well balanced article. I now understand that it makes sense to wait before investing in PHEV battery suppliers, until the fog has cleared out.

In the meantime, I will continue to drive my 45mpg turbo diesel VW Golf using $6.8 per gallon 90% fossil diesel and 10% biodiesel, given that this diesel mix is 20% cheaper than regular petrol gas, to help truckers while discouraging the use of massive SUV’s.

Lithium-Ion batteries, a square peg being forced into a round hole. The Leaf is proof that it isn’t the right technology for the application. I engineer by the expression “The application dictates the design”. This whole lithium-Ion battery race is firms scamming investors and the government. EEstor is an ongoing scam that will never deliver a product.

The other scam and pie in the sky thinking is hydrogen powered cars. The following link proves how ridiculous the idea is.

http://planetforlife.com/h2/h2swiss.html